MERIT

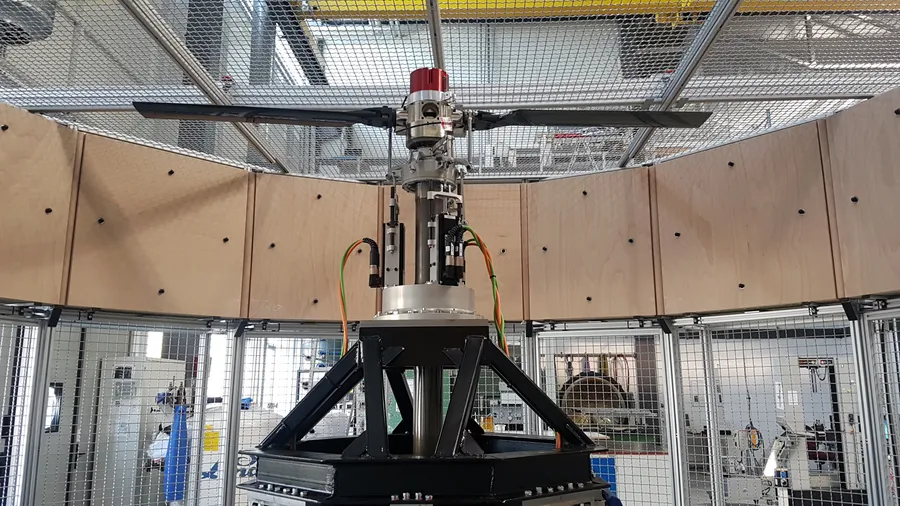

Munich Experimental Rotor Investigation Testbed

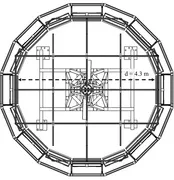

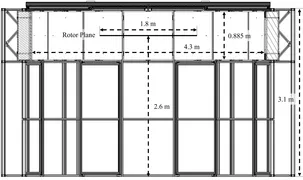

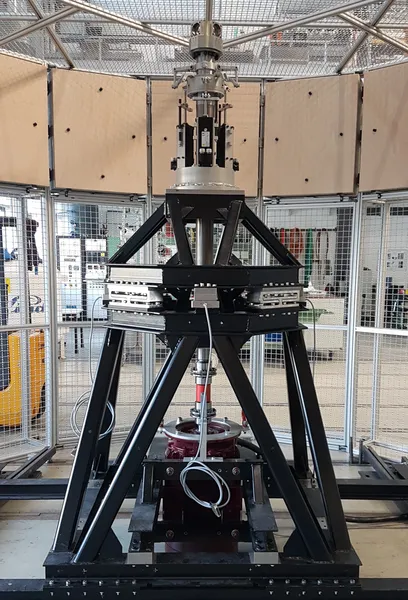

Der MERIT Prüfstand wurde allgemein für Rotor- und Propellorversuche ausgelegt. Das robuste und kompakte Design ermöglicht dynamische und hochlastige Versuchsanwendungen, z.B. den schnellen Vorwärtsflug. Während des Auslegungsprozesses war ein Hauptkriterium die kompatibilität mit dem Windkanal A vom Lehrstuhl für Aerodynamik und Strömungsmechanik um solche Messkampagnen zu ermöglichen.

Leistungsdaten

| 3000 RPM |

| 85 kW |

| 270 Nm |

| +/- 30° pitch (collective + cyclic) |

| 1,2,4 Rotorblätter |

| 2.6 m Rotorhöhe |

Messtechnik

| Induktive Telemetrie: 34 k., 20 kHz p. k., 16 bit, MANNER (DMS, Instationäre Drucksensoren) | |

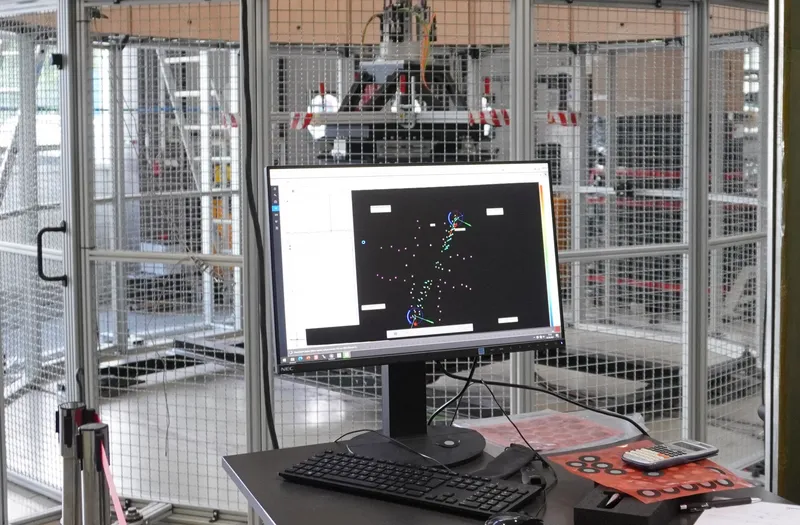

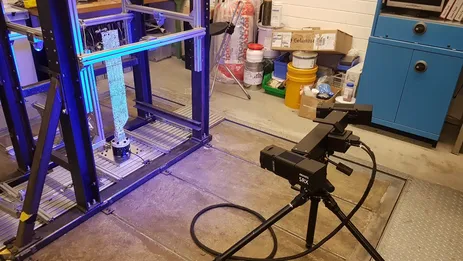

| DIC/Fotogrammetrie: ARAMIS SRX 1600 MV4200 HD 1000 Hz (Blattdeformationsanalyse) | |

| Rotierende FBG System: FBG-Scan 80X, 8 optische k., 250 Hz p. k. (Blattdeformationsanalyse) | |

| 4 Kraftmessdosen K3D120, ME Meßsysteme (Rotorlasten) | |

| 1 Drehmoment & Geschwindigkeitssensor DATAFLEX32, KTR | |

| 1 Rotor geschwindigkeitssensor IH150, Globalencoder | |

| 4 pitch Hallsensor PMIS4-20-40, ASM |

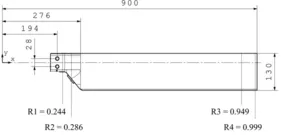

Rotorblätter

| MERIT | |

|---|---|

| R = 0.9 m | |

| c = 0.13 m | |

| NACA0012 0° tab | |

| gelenklos | |

| keine Zusammenspitzung | |

| kein Twist |

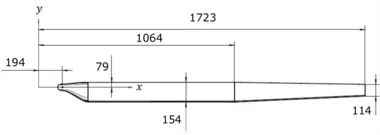

| AREA | |

|---|---|

| R = 1.723 m | |

| c = 0.114-0.154 m | |

| NACA 23012 | |

| Schwenkgelenk | |

| Zusammenspitzung: 0.6, linear | |

| -10° Twist |

Gehäuse

Aktuelles

Das Digital Image Correlation Equipment und Methodik wurde mit dem AREA Blattsatz angewandt, und MERIT und AREA Blätter wurden bis zum Strömungsabreißkollektivwinkel gezogen. Die Deformation der Blätter in diesen extremen Bedingungen wurde erforscht und veröffentlicht.

AREA: 500-900 rpm, 0°-18° Kollektivwinkel

MERIT: 900-1500 rpm, 0°- 24° Kollektivwinkel

- 900, 1200, 1500 rpm

- 14° +/- 1,2,...,10°

- 16° +/- 1,2,...,8°

- 18° +/- 1,2,...,6°

- 20° +/- 1,2,...,6°

-4°,-3°,...,24° Kollektivwinkel

900, 1200, 1250 rpm

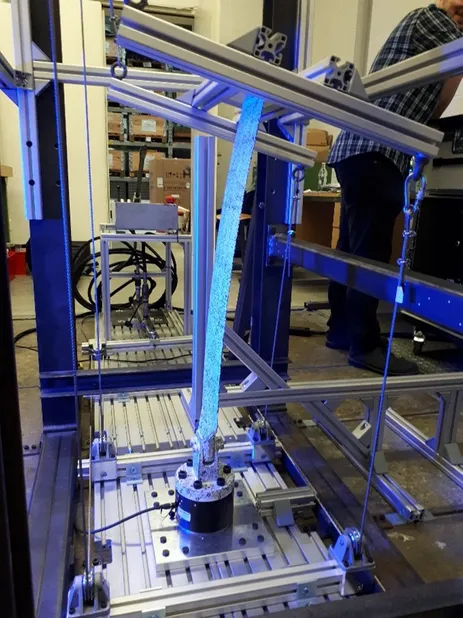

Mit Hilfe von Gunter Sanow und Daniel Maraite von Zeiss GOM GmbH, wurde das Digital Image Correlation Equipment mit dem ARAMIS SRX Sensor bei einer Maximalbildrate von 1000 Hz eingesetzt, um die Blattdeformation des MERIT Blattsatztes bei 900 und 1800 rpm und bis zu 12° Kollektiv zu messen (09-2021)

AREA Rotorversuch bei 680 rpm Nominaldrehzahl und bis zu 4° Kollektivwinkel

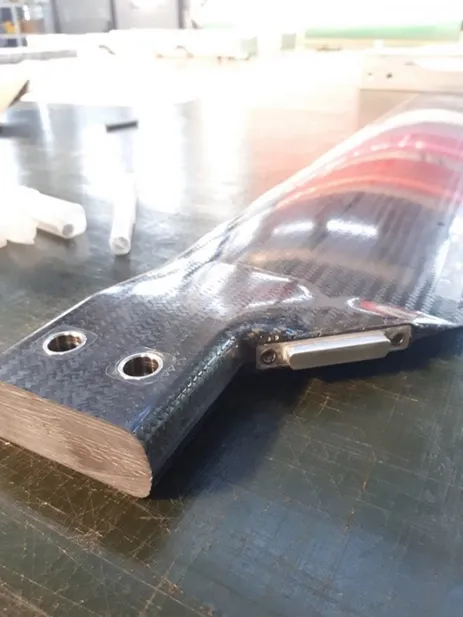

Die Blätter die für die dynamischen Strömungsabrissexperimente verwendet werden haben keine Verwindung, eine rechteckige Grundrissform, ein NACA0012-Profil, 130 mm Sehne und einen Radius von 900 mm. Die Struktur besteht aus einem Kohlenstofffaser-C-Sparren mit Bleigewicht und einem Lagerlaminat mit zwei Bolzen an der Befestigung zum Rotormast. Ein integrierter Steckverbinder bietet die notwendige Schnittstelle für mögliche Messgeräte wie Dehnungsmessstreifen oder Instationäre Drucksensoren.

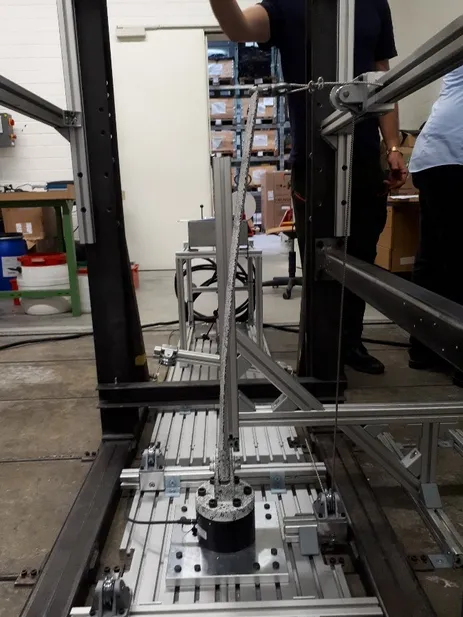

Wir haben SONATA, VABS und ANBA4 für die Auslegung der Querschnittseigenschaften verwendet. Die ersten statischen Strukturtests wurden kürzlich durchgeführt mit dem Ziel, die vorhergesagten Balkeneigenschaften experimentell zu verifizieren mit digitaler Bildkorrelation (DIC)

Ohne die große Hilfe von Daniel Maraite von Zeiss GOM, der uns mit einem ARAMIS SRX-Sensor unterstützt hat, und die kontinuierliche Unterstützung von VABS von Analyswift wäre diese Arbeit nicht möglich gewesen.

Unser Dank gilt auch dem TUM-Labor für Produktentwicklung und Leichtbau, dem TUM-Lehrstuhl für Carbon Composites und der TUM Werkstatt des Fachbereichs Physik für ihre großzügige Unterstützung!

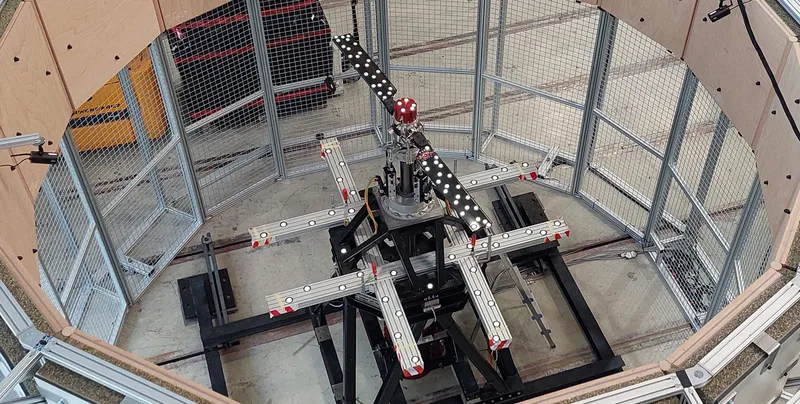

Betrieb bei niedriger Drehzahl mit Aktuatoren, Taumelscheibe und Rotorkopf im Sicherheitsbehälter (01-2020)

Erfolgreiche Montage des Rotorantriebssystems (03-2019)

Veröffentlichungen

Heuschneider, V., Yavrucuk, I., and Hajek, M.: Structural Blade Loads on a Rotor during Dynamic Stall in Hover, Proceedings of the Vertical Flight Society`s 80th Annual Forum & Technology Display, Montréal, Québec, Canada. May 7-9, 2024.

Baldan, G., Heuschneider, V., Mitropoulos, M., Yavrucuk, I., and Guardone, A.: Numerical and Experimental Investigation of Stall on the MERIT Rotor in Hover, Proceedings of the Vertical Flight Society`s 80th Annual Forum & Technology Display, Montréal, Québec, Canada. May 7-9, 2024.

Mitropoulos, M., Heuschneider, V., Barth, A., and Yavrucuk, I.: Experimental Whirl Tower Tests Approaching and Surpassing Stall for a Variety of Tip Speeds and Rotor Blades, Proceedings of the Vertical Flight Society`s 80th Annual Forum & Technology Display, Montréal, Québec, Canada. May 7-9, 2024.

Berghammer, F., Sosa, B., Heuschneider, V., Yavrucuk, I., and Hajek, M.: Testing of a Fiber-Optical Sensor System for Rotor Blade HUMS, Proceedings of the Vertical Flight Society`s 79th Annual Forum & Technology Display, West Palm Beach, Florida, USA. May 16-18, 2023.

Heuschneider, V., Berghammer, F., Abdelmoula, A., Hajek, M., and Sirohi, J.: Model Based Blade Attachment Stiffness Evaluation of the MERIT Rotor in Hover with Photogrammetry and Digital Image Correlation, Proceedings of the Vertical Flight Society’s 78th Annual Forum & Technology Display, Fort Worth, Texas, USA. May 10-12, 2022.

Berghammer, F., Heuschneider, V., and Hajek, M.: Development And Integration Of A Fiber-Optical Sensor System For Rotor Blade State Observation, Proceedings of the Vertical Flight Society’s 78th Annual Forum & Technology Display, Fort Worth, Texas, USA. May 10-12, 2022.

Heuschneider, V., Berghammer, F., Pflumm, T., and Hajek, M.: Development and Initial Hover Testing of the Mach Scaled Rotor Test Rig MERIT, Proceedings of the 47th European Rotorcraft Forum, Royal Aeronautical Society, Virtual, September 2021.

Pflumm, T., Gaugelhofer, L., Heuschneider, V., Berghammer, F., and Hajek, M.: Hybrid Experimental Measurement of Sectional Stiffness Properties of the MERIT Rotor Blade with Digital Image Correlation, Proceedings of the 47th European Rotorcraft Forum, Royal Aeronautical Society, Virtual, September 2021.

Heuschneider, V., Berghammer, F., and Hajek, M.: Numerical and Experimental Study on the Modal Characteristics of a Rotor Test Rig, Society for Experimental Mechanics, Topics in Modal Analysis & Testing, Volume 8, Proceedings of the 38th IMAC, A Conference and Exposition on Structural Dynamics 2020.

Kontaktinformationen

Matti Mitropoulos, M.Eng. (Prüfstandsbetrieb, Digitale Bilkorrelation im Rotierendem System)

Verena Heuschneider, M.Sc. (Prüfstandsauslegung, Messtechnik und Betrieb, Dynamische Strömungsabrissmesskampagnen)

Tobias Pflumm, M.Sc. (Rotorblatt Auslegung & Konstruktion)

Florian Berghammer, M.Sc. (FBG Sensor Integration, Blattdeformationen im Rotierendem System)