DRIVER

Grant Number: 20E1914

Short Description

The DRIVER project aims to explore a new design concept for highly loaded axial compressors using tandem airfoils with high flow turning and efficiency, with further new technologies to be developed to influence the flow in the endwall regions in a loss-reducing manner.

The investigated compressor configuration promises higher efficiency while increasing the aerodynamic loading of the stage. In addition, the overall pressure ratio of an aircraft engine, which is limited in the number of stages, can thereby be further increased, and the core engine size can be further reduced in favor of an increased bypass ratio. The compressor and engine system benefits of the new technology alone can lead to fuel consumption and emissions (CO2 and NOX) savings of up to 5%, according to FP2020 targets. In addition, there are weight and cost advantages.

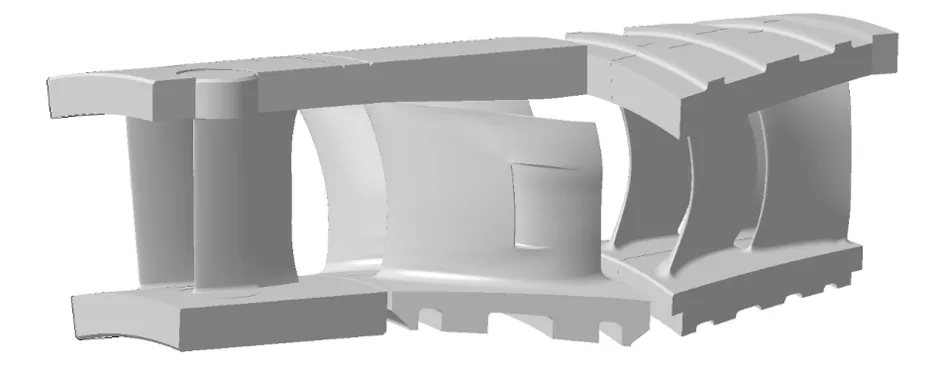

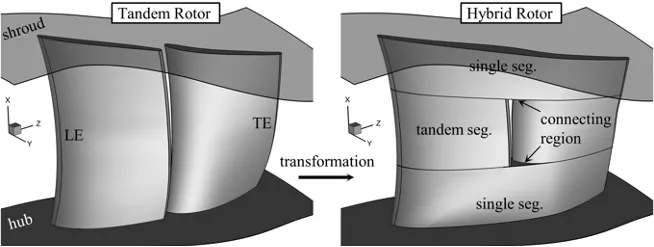

The project deals with the establishment of a numerical process chain for the systematic investigation of the design space of highly loaded stage configurations (ψ≈0.73). The entire design process from the 2D through-flow method to 3D geometry generation, simulation and optimization is represented. The method allows the investigation and optimization of conventional rotor and stator geometries, and especially unconventional geometries, such as the hybrid rotor and tandem stator configuration like the one shown in Figure 1. For the generation of the hybrid geometry, a previously developed tandem is always used (see figure 2). Near the endwalls, envelopes of the front and rear vanes form single blade segments, which are intended to reduce secondary flow losses in this regions.

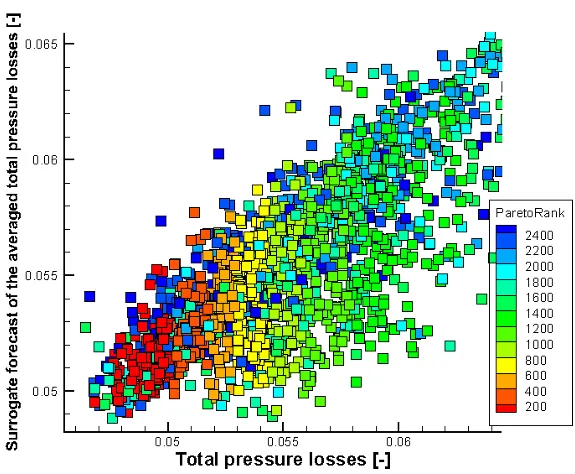

For the 3D optimization, the meta-heuristic optimizer AutoOpti of DLR is used. The handling of multi-objective functions (e.g. total pressure ratio and efficiency) is enabled in AutoOpti by the definition of the Pareto rank, which allows to improve the objective functions considering the set constraints. An example of a Pareto rank definition of a robust optimization is shown in Figure 3.

The numerical process chain is validated by an experimental investigation of the developed blading and endwall concepts in a low-speed research compressor. The 3.5-stage research compressor used sets the geometric constraints for the aerodynamic design. A blading, consisting of a tandem stator and a conventional rotor, is already being tested on this test rig. This serves as a reference for the DRIVER project. A comparison of the DRIVER and the reference setup is shown in Table 1.

Tabelle 1: Vergleich des DRIVER und des Referenzaufbaus

| Reference | DRIVER | ||

| Machrel at rotortip | 0.25 | 0.23 | |

| Design rot. speed | 1484 rpm | 1261.4 rpm | |

| Design masslflow | 17.92 kg/s | 15.232 kg/s | |

| Rotor tip speed at DP | 85.86 m/s | 71.41 m/s | |

| Design flow coefficient φD | 0.57 | 0.57 | |

| Design work coefficient ψD | 0.56 | 0.73 |

The results of the research project will contribute significantly to a better understanding of the tandem/hybrid configuration and thus enable the generation of recommendations and guidelines for the design of highly-loaded compressors.

The research project is funded by the aerospace research program (LuFo VI-1) of the German Federal Ministry for Economic Affairs and Energy (BMWi).

Aim / Objective

· Introduction of the tandem principle for the rotor, leading to a so-called hybrid rotor

· Influencing the endwall boundary layers in the tandem stator

· Stabilization of the tip leakage flow at the hybrid rotor