Unsteady Tandem Flow

DFG Grant Number 420268957

Short Description

The aviation industry is working on increasing the efficiency of aircraft engines. One way of increasing the stage loading of turbocompressors is to use tandem blades. In a tandem blade design, the classic single-element blade profiles are replaced by multi-element profiles within a blade row. There is a gap between the profile elements.

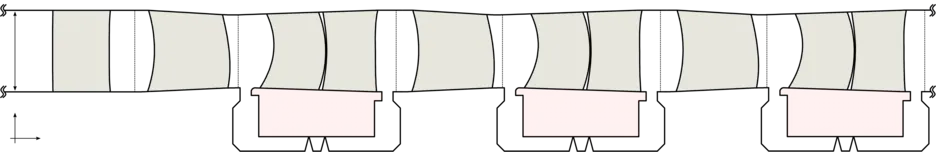

The aim of the project "Unsteady Tandem Flow" is to numerically and experimentally investigate the flow through tandem blades in a multistage axial compressor, whose dimensionless coefficients are representative for high-pressure compressors of aircraft engines. For this purpose, the 3.5-stage low-speed axial compressor test rig FRANCC, which was newly built at the institute, is equipped with a tandem stator in all stages. The figure below shows a schematic section through the compressor.

While the time-averaged behavior of tandem profiles has already been investigated numerically and experimentally in cascade tests in several research projects, the time-dependent flow behavior is largely unknown so far. Therefore, this project investigates the fundamentals of time-dependent, viscous and three-dimensional flow through tandem blade rows in the machine environment of a multi-stage compressor. Both the time-dependent influence of the rotor on the flow of the tandem stator (rotor-stator interaction) and the influence of the wide wake of a tandem stator on the following rotor bladerow (stator-rotor interaction) are of interest.

Aim / Objectives

The research project is divided into two project phases. Project phase I includes the following investigations:

- Aerodynamic design of the compressor

- Numerical investigation of the steady-state flow of the first 1.5 stages, as well as of the entire 3.5-stage compressor

- Numerical investigation of the transient flow of the 1.5-stage compressor

- Experimental investigation of the operating behavior of the machine, as well as the time-averaged flow of the tandem stator

- Time-resolved measurement of the flow through the tandem stator row using hot-wire measurement technology

In the currently applied project phase II, the following investigations are planned:

- Numerical investigation of the transient flow through the 1.5-stage and 3.5-stage compressor

- Numerical investigation of the influence of real inlet conditions on the operating behavior of the machine

- Numerical investigation of the boundary layer transition on the tandem profiles

- Numerical investigation of the stator positioning (clocking)

- Measurement of the profile pressure distribution at the tandem stator

- Time-resolved measurement of the flow through the tandem stator using a fast-responding pressure probe

- Experimental investigation of the boundary layer transition at the tandem profiles using surface hot-film technique

- Measurement of the flow through the tandem passage using of Particle Image Velocimetry (PIV)