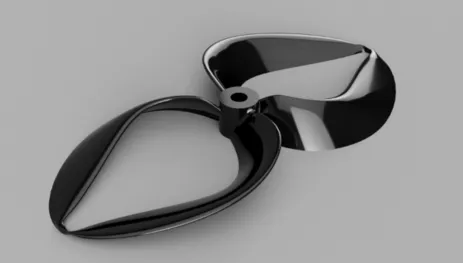

TorPropel –Toroidal Propellers for Efficient and Sustainable Aviation

Development of the toroidal propellers using advanced carbon composites and robotic manufacturing, enhancing performance, sustainability, and noise reduction..

Project Partners

University of Ioannina, ICOMAT, Evektor, Limmat Scientific, Aristotle University of Thessaloniki, GMI Aero, Brunel University London

Duration

02.01.2025 – 31.01.2028

Further Links

Official Webpage of the European Commission: https://cordis.europa.eu/project/id/101187800

Funding authority

European Union, Horizon Europe

Motivation

The TorPropel project aims to transform aircraft propulsion by advancing toroidal propeller designs using advanced carbon composites and robotic manufacturing processes. This technology promises to enhance the performance of a wide range of aircraft, from small electric planes and vertical take-off and landing aircraft to UAVs and new distributed propulsion systems. Building on the award-winning MIT Lincoln Laboratory toroidal propeller, which showed improved thrust efficiency and noise reduction in small-scale tests, TorPropel seeks to scale this design for larger airframes. The project addresses optimization, manufacturing, and safety challenges, ultimately improving propeller performance, durability, weight, sustainability, and paving the way for quieter, more environmentally friendly air travel.

Method

The TorPropel project follows a structured methodology to achieve TRL4 through systematic testing. It begins with aerodynamic optimization using Computational Fluid Dynamics (CFD) to improve thrust efficiency and reduce noise, followed by composite structure optimization for performance enhancements. Advanced epoxy vitrimer composites are developed for high mechanical properties, thermal resistance, and recyclability. Robotic manufacturing, particularly Rapid Tow Shearing (RTS), ensures precise fiber placement and structural integrity. A structural health monitoring (SHM) system tracks real-time conditions and enables predictive maintenance. After fabrication, propellers undergo performance validation, while a lifecycle analysis assesses environmental impacts to align with sustainability goals.

Acknowledgement

The chair thankfully acknowledges the funding for the project “TorPropel” provided by the European Union under the “Horizon Europe” Program Grant number 101187800. This project has received funding from the European Union‘s Horizon Europe research and innovation program. This content reflects only the author‘s view and that the European Commission is not responsible for any use that may be made of the information it contains.

Contact Persons

Noor Rehman, M.Sc.; Dipl.-Ing. Thomas Wettemann