SULUWHIR – Supported Lay-Up with High-Performance Resin

Development and optimization of a vacuum infusion process based on the SULU principle.

Project Partners

Kaelin Aero Technologies GmbH, Röder Präzision GmbH

Duration

01.01.2024 – 31.12.2025

Funding authority

Federal Ministry for Economic Affairs and Climate Action

Motivation

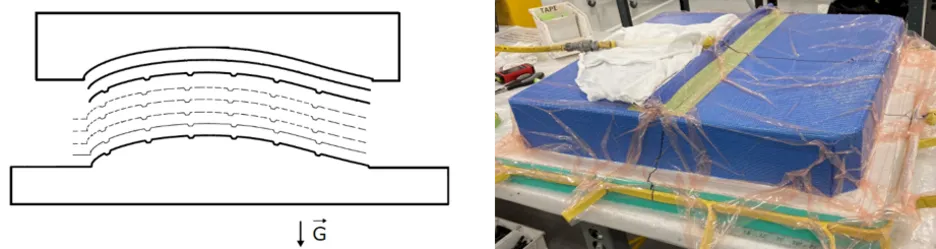

The ZIM cooperation project SULUWHIR focuses on developing efficient and cost-effective manufacturing processes for lightweight aircraft structures made of composite materials. Due to the high demands on precision and quality of the components, a process based on vacuum infusion will be used and further developed. A lay-up tool will optimize the positioning of the materials. Additionally, the infusion process will be improved in terms of impregnation quality and cycle time. A simulation method will be developed to realistically depict the process. This procedure will ultimately be applied to the production of complex demonstrator components to enhance manufacturing efficiency and product quality.

Method

In the SULUWHIR project, TUM is developing a vacuum infusion process for manufacturing lightweight aircraft structures. Initially, the partners are advised on design and component development to integrate process-specific aspects. Then, materials are characterized, and design guidelines and process parameters are established. A simulation of the infusion process is created and compared with real data to optimize the process. Subsequently, the optimized infusion process is applied to complex demonstrator components and tested in manufacturing trials. The results are scaled, and a manufacturing specification is created to enable the partners to achieve efficient production.

Acknowledgement

The Chair thanks the Federal Ministry for Economic Affairs and Energy for funding the SULUWHIR project (Grant Number KK5135819KL3).

Contact Persons

Maximilian Steinhardt, M.Sc.; Dr.-Ing. Swen Zaremba