HySTHra – Hybrid SMC-TFP Rear Frame

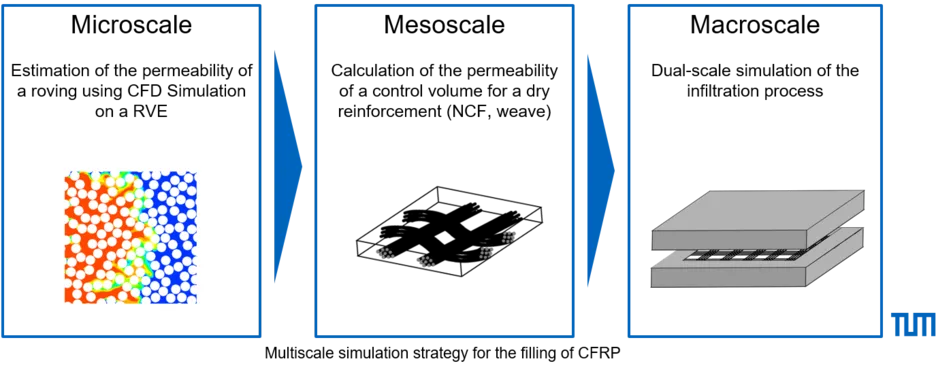

At TUM-LCC a study of the micro-/ macroflow is carried out, to investigate the impregnation behavior of dry CFRP preforms.

Project Partners

Biontec Composite Technologies AG, Blackwave GmbH, Propain Bicycles GmbH

Duration

01.11.2018 – 30.09.2021

Funding authority

Federal Ministry for Economic Affairs and Energy

Motivation

CFRPs are used in various industries due to their lightweight potential. In addition to the aerospace and automotive industry, the advantages of the composite material can also be implemented in sports equipment. In order to reduce the production cost, processes in which the impregnation of the textile takes place simultaneously with the curing, are used. Filling simulations help optimizing these processes. For this purpose, a permeability of the textile is usually determined at macroscale. According to the current state of research, this approach insufficiently reflects the impregnation processes of the textile at the microscale for the prediction of defects. Instead, a dual scale simulation, which takes the impregnation of the fiber bundles into account, is the focus of current research.

Method

To determine the impregnation behavior of dry fiber preforms, a multiscale simulation method is used. Starting with the microscale, the flow of resin through a roving is simulated using CFD. Calculated substitute permeabilities are then used to investigate textile architecture (mesoscale). The properties of NCFs, weaves and TFP preforms are characterized in terms of impregnation. With these results as input variables, the simulation of the filling process of the entire preform is conducted at the macroscale. Analogous to the simulative approach, new methods for the experimental determination of the permeability at micro and macro level are performed to validate the simulation.

Acknowledgement

The Chair of Carbon Composites thankfully acknowledges the funding provided by would like to thank the Federal Ministry for Economic Affairs and Energy for promoting the HySTHra project within the funding program "Central Innovation Program for SMEs".

Contact Persons

Maximilian Steinhardt, M.Sc.; Dr.-Ing. Swen Zaremba