COOPERATE – CO2-neutral, lifetime-optimised, short-fibre reinforced thermoplastics for dynamic applications

The project COOPERATE is promoting methods to fundamentally improve product design and layout in terms of structural lightweight performance, life cycle assessment and sustainability of bio-based, injection molded plastic and short fiber-reinforced components.

Project Partners

BOGE Elastmetall GmbH, TECNARO GmbH, Fraunhofer-Institut für Betriebsfestigkeit und Systemzuverlässigkeit LBF

Duration

01.11.2021 – 30.10.2024

Funding authority

Federal Ministry for Economic Affairs and Climate Action of Germany

Motivation

There is great potential for reducing emissions in product development. By reducing the amount of material used and using bio-based composites, the CO2 requirement in the production of short fiber-reinforced injection molded plastic components is to be reduced by up to 75 percent. The project partners are jointly developing material-saving design methods and bio-based composites for durable and highly structurally loaded components - with concrete application examples from the field of automotive engineering serving as a benchmark. The new methods and the improved material properties pave the way for the use of new plastics in other fields of technology. The COOPERATE project is pursuing the goals of lightweight construction-related development of resource-efficient processes and the substitution of greenhouse gas-intensive materials. The use of bio-based materials achieves significant savings in material-related greenhouse gas emissions. Since bio-based materials achieve a different performance than conventional materials, the climate-neutral substitutes are being further developed in this project and practice-relevant investigations of the material properties are being carried out with regard to structurally important characteristic values.

Method

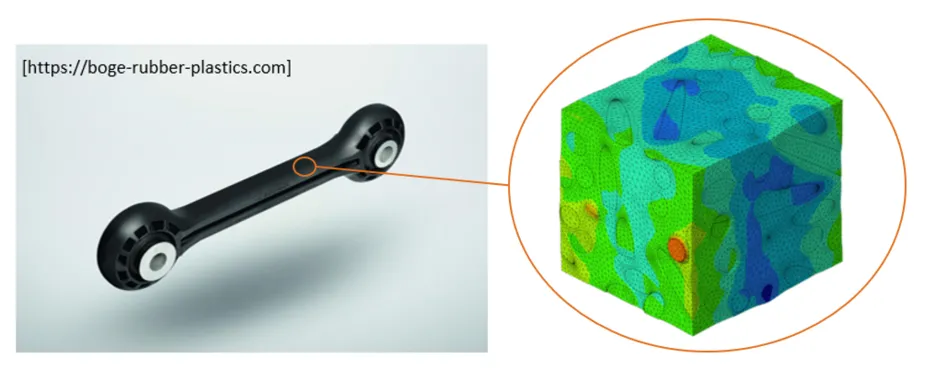

In order to reduce the amount of material used, the design processes are to be improved for use in consumer goods subject to vibrations. This will increase the lightweight construction potential and the associated resource efficiency. New calculation methods are being developed that take into account the influences of manufacturing on the quasi-static and dynamic behaviour of the materials. A prerequisite for exploiting the lightweight construction potential is the precise characterisation of the materials used and the validation of the simulation methods. Our responsibility in the project includes the development of a simulation environment for the virtual characterization of the novel short fiber-reinforced material in the form of micro-mechanical cell homogenization. Injection molding technologies inherit some process-induced effects on the material properties. Therefore, the injected composite material has a complex micro-macro coupled mechanical behavior. This must be investigated thoroughly before injection molded components can be integrated into structural applications in automotive industry. Furthermore, our target is the development of a comprehensive life-cycle model (LCA) for the evaluation of CO2 footprint of the entire material and manufacturing process chain.

Acknowledgement

The chair thankfully acknowledges the funding provided by the Federal Ministry for Economic Affairs and Climate Action of Germany (Funding code: NW-1812-0006). Furthermore, the co-operation with project partners is highly appreciated.

Contact Persons

Oliver Schwahofer, M.Sc.; Dr.-Ing. Swen Zaremba