Schneckoplast - Development of a screw extruder with a moveable cylinder core for co-extrusion-based 3D printing of natural fiber-reinforced thermoplastic material

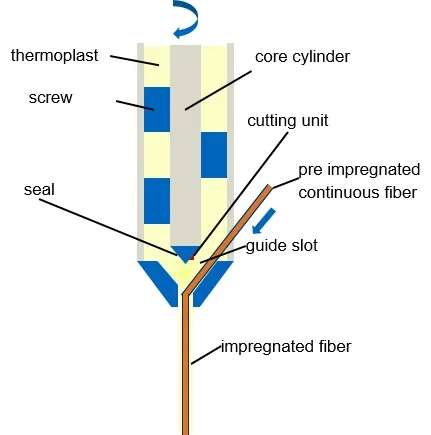

In the Schneckoplast project, a screw extruder with a sealing mechanism is being developed to prevent unwanted material discharge. In addition, an extrusion head for the coextrusion of continuous fibers is being designed.

Project Partners

Franz Rieger GmbH Formen- und Musterbau

Duration

01.01.2023 - 31.06.2025

Funding authority

Federal Ministry for Economic Affairs and Energy

Motivation

Due to the high material output and lower material costs, screw extruders are becoming increasingly popular in extrusion-based additive manufacturing. However, these are associated with very high equipment costs. In addition, targeted load path-related reinforcement with fibers is not possible due to the feedstock (granulate). While in conventional FFF printers, pulling back the material prevents an unwanted material discharge, this is not possible due to the pressure prevailing in the screw extruder. The Schneckoplast project will address these problems, and new possibilities and systems will be developed and manufactured.

Method

The project aims to develop a compact screw extruder that can print both with and without continuous fibers while at the same time allowing a variable layer width without having to change the nozzle. One of the biggest problems with this is that with the frequent starting and stopping of screw extruders in 3D printing, melt runs out of the nozzle after the rotation of the screw stops due to the pressure built up. Therefore, a new nozzle closure technology is being developed for the planned compact extruder. In addition, an extrusion head is being designed for the coextrusion of continuous fibers. This way, components can be printed cost-effectively (using pellets) and reinforced with continuous fibers. The continuous fiber coextrusion unit, as well as material selection and prototype construction, will be covered by TUM.

Acknowledgement

The chair thankfully acknowledges the funding provided by the Federal Ministry of Economic Affairs and Energy as well as the AiF Projekt GmbH for the ZIM R&D Project “ Schneckoplast - Development of a screw extruder with moveable cylinder core for co-extrusion-based 3D printing of natural fiber-reinforced thermoplastic material” (funding code: KK5135816HD2)

Contact Persons

Daniela Schreil, M.Eng.; Dr.-Ing. Swen Zaremba