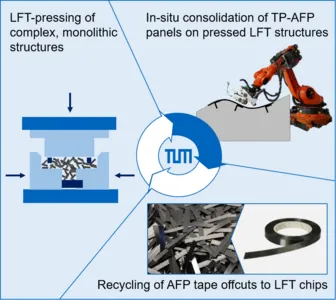

REUSELAGE – Development of a process for manufacturing pressed thermoplastic CFRP components from tape offcuts with subsequent in-situ consolidation of TP-AFP structures

Production-ready process development for pressing long-fibre-reinforced components from tape offcuts with subsequent in-situ consolidation of TP-AFP structures.

Project Partners

Eckerle GmbH

Duration

01.05.2020 – 31.08.2022

Funding authority

Federal Ministry for Economic Affairs and Energy (BMWi)

Motivation

During the production of CFRP structures using Thermoplastic Automated Fibre Placement (TP-AFP) on an industrial scale, there are waste residues of up to 20%. These high quality tape offcuts are today disposed of as hazardous waste. At the same time, the high prices of carbon fibre reinforced materials are a limiting factor for the economic use of carbon composites. Therefore, there is a need for a process that enables the further processing of the material residues. For this purpose, a pressing process for long fibre reinforced thermoplastics (LFT) made of tape offcuts with subsequent in-situ consolidation of TP-AFP panels is being developed. This technological approach promises particular potential through integral design, reduction of joining processes, recycling of production waste and recyclability through "one material".

Method

The goal of ReUselage is to develop a production-ready process chain for manufacturing hybrid continuous and long fibre reinforced thermoplastic components. The main challenge of ReUselage is the production of LFT components made of recycled CF/PEEK tape offcuts from the TP-AFP process. First of all, a process for the preparation of tape residues into defined tape chips is developed. Subsequently, the process of LFT pressing is developed taking into account the process parameters chip geometry, pressure and temperature as well as the target factors cycle time and part quality. In the course of the process development, a test tool for setting the process parameters as well as the tool of a demonstrator part, including demoulding system, active heating and cooling circuits and evacuation concept will be manufactured. Finally, the in-situ consolidation of continuous fibre reinforced components to pressed LFT components is investigated. For this purpose, a tool for the integration of LFT structures into the TP-AFP process is developed and options for the optimal bonding between long-fibre and continuous fibre-reinforced components are analysed.