MEX-DES – Additive Manufacturing by Materialextrusion with Directed Energy Substrate Preconditioning

Development of a 3D printing process for large-scale continuous carbon fiber reinforcement with the help of laser technology.

Project Partners

Dr. Mergenthaler GmbH & Co. KG, Dyze Design

Duration

01.12.2019 – 24.12.2021

Funding authority

Federal Ministry for Economic Affairs and Energy

Motivation

The objective of this project is to enable the additive manufacturing (also known as 3D printing) of high-performance plastics with fiber reinforcement on a large scale. For the large-size parts manufacturing, the interlayer bond strength and the thermal residual stress greatly influence the geometry accuracy and the mechanical properties of the printed pieces. Thus, extrusion is combined with another 3D printing process, “Directed Energy Deposition,” to enhance the joining between layers and ensure high printing quality. A new 3D printing approach based on material extrusion and directed energy processes is developed to manufacture large-size parts with local fiber reinforcement.

Method

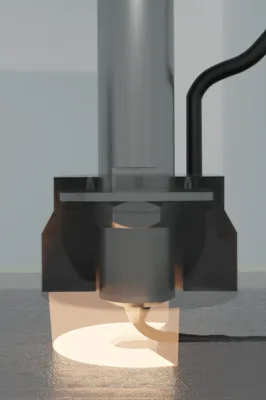

A laser system is first developed for the preconditioning of the substrate materials. The substrate is heated into the melting state before the material deposition so that the fusion between the substrate and printed structure can be enhanced. A control system to coordinate the activities of the extruder, laser generator, and the kinematic system is then proposed to guarantee the homogenous heating on various surfaces of different materials, even on curved surface. To give this new manufacturing process more possibility and flexibility, the developed system will be integrated into an industrial robotic arm.