MATISSE – Shape-Adaptive Side Impact Beam from CFRP for Alternatively Powered Vehicles

Shape-adaptive, inflatable hollow structures are a solution for the development of effective vehicle crash-structures to cope with current safety requirements and limited design space. On the basis of a hybrid matrix approach, elastomer and thermoset matrix materials were combined in one CFRP component. Tests of an inflatable prototype of a side impact beam reveal the potential of this technology regarding increase of bending stiffness as well as reduction of deflection.

Project Partners

fka Forschungsgesellschaft Kraftfahrwesen mbH Aachen, Graz University of Technology, Centro Ricerche FIAT S.C.p.A., Daimler AG, Autoliv Development AB, DYNAmore Nordic AB, Sistemas y Procesos Avanzados S.L., Chalmers University of Technology, Airborne Technology Centre B.V.

Duration

01.10.2012 – 30.09.2015

Funding authority

FP7-TRANSPORT - Specific Programme "Cooperation": Transport (including Aeronautics) of the European Union

Motivation

Car concepts of today and especially small electrically driven vehicles of tomorrow increase the safety risk for passengers due to their low mass and lack of deformation zones. Small electric vehicles come with new requirements regarding safety that can only be solved by innovative and effective crash structures. Shape-adaptive crash structures that can be inflated are a solution to cope with these new requirements. Reduced design space, improved crash performance combined with reduced weight and the possibility to increase stiffness on demand via inflation by inside pressure help to improve passenger safety in these new vehicle concepts.

Method

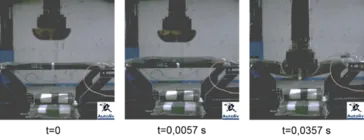

Focus of the project was the development of a shape-adaptive side impact beam made from carbon fiber reinforced plastics. By means of a highly dynamic application of inside pressure, the beam changes its cross section and thereby its stiffness properties. The defined change in geometry is possible due to its hybrid matrix design. Elastomer matrix components are locally combined with a thermoset matrix material. For production of the component, compatible matrix systems are co-infiltrated at the same time. At predefined transition zones, the simultaneously processed matrix systems mix with each other and are subsequently co-cured. The results of the crash tests in a 3 point bending setup illustrate the potential of the application of inside pressure and the shape-adaptivity of the impact beam: The initial stiffness as well as the maximum force are significantly elevated and the maximum deflection in comparison to the structure without inside pressure is considerably reduced.

Publications

Krollmann, J.; Opelka, J. M.; Nohr, M.; Pipkorn, B.: Formadaptiver Seitenaufprallträger aus faserverstärktem Kunststoff. Lightweight Design, 9, 2016, 12-17.

Brouzoulis, J.; Fagerström, M.; Främby, J.; Krollmann, J.; Hellström, P.: Modelling of propagating delaminations in textile reinforced duroplast beams by an enriched shell element formulation. ICCM-20 - 20th International Conference on Composite Materials, 2015

Gstrein, G.; Kurzböck, C.; Opelka, J-M.; Krollmann, J.: Simulation and testing of adaptive FRP- substructures for automotive safety. 24th International Technical Conference on the Enhanced Safety of Vehicles (ESV), 2015

Krollmann, J.; Snajdr, R.; Paz, M.; Zaremba, S.; Drechsler, K.: Hybrid-matrix approach: How to overcome the conflict of the matrix selection? Polymer Processing Society Conference (PPS) 2015, 2015

Acknowledgement

This project has received funding within the framework of the FP7-TRANSPORT - Specific Programme "Cooperation": Transport (including Aeronautics) of the European Union under grant agreement No 314182 (“Modelling And Testing for Improved Safety of Key Composite Structures in Alternatively Powered Vehicles”). This publication reflects only the author’s views and the European Union is not liable for any use that may be made of the information contained therein.

Contact Persons

Dipl.-Ing. Kalle Kind; Dr.-Ing. Swen Zaremba

Final Report

Download (pdf)