InSensoFlecht – Integrated Sensor System for Monitoring the Braiding Process

To reduce material waste and machine downtime during braiding of carbon fiber, we have developed a novel kind of online monitoring system which is able to avoid and detect the development of braiding defects already in early stages.

Project Partners

Barthels-Feldhoff GmbH & Co. KG, Körting Nachf. Wilhelm Steeger GmbH & Co. KG, Gemini Business Solutions GmbH

Duration

01.06.2017 – 31.05.2019

Funding Authority

German Federal Ministry of Education and Research

Motivation

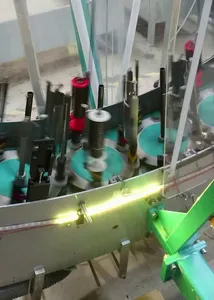

Braiding is a highly automated process for the production of technical textiles or the manufacture of predominantly tubular preforms directly from carbon fiber yarns. The quality of the braids and the stability of the process may however be negatively influenced by production defects. Since these defects can cause material waste and machine downtime, machine productivity is reduced and additional costs for error cause analysis and error correction time arise. Especially in the case of large braiding machines with several hundreds of yarns, the search for the error cause can be time consuming and therefore contributes to longer machine downtime.

Method

The newly developed modular sensor system is now capable of substantially reducing scrap rates and machine downtime of braiding machines by means of an automated monitoring of the whole braiding process chain. Two concepts were developed in order to prophylactically avoid error causes during the upstream rewinding step. Moreover, if a defect cannot be avoided, five measurement principles comprising sensors that are stationarily attached to the body of the machine (bobbin carrier independent) were established for detecting defects during the braiding step as early as possible before they manifest in the product. In order to ensure a quick error cause analysis and correction, the braiding machine is stopped, the position of the error cause in the machine is calculated by a self-learning algorithm and indicated to operating personnel by a light signal.

Publications

AVK - Industrievereinigung Verstärkte Kunststoffe (Federation of Reinforced Pastics): AVK-Innovation Award brochure 2019, URL: www.avk-tv.de/files/20190912_1905126_avk_broschuere_innovationspreis_ansicht.pdf

Maidl, S; Sabieraj, M; Mierzwa, A; Ebel, C; Drechsler, K: Investigating the unwinding behavior of technical yarns and development of a new sensor system for the braiding process. IOP Conference Series: Materials Science and Engineering 406, 2018

Maidl, S; Mierzwa, A; Ebel, C; Drechsler, K.: Development of a novel type of online monitoring system for the braiding process. ECCM18 - 18th European Conference on Composite Materials, 2018

Acknowledgement

The chair thankfully acknowledges the funding provided by the German Federal Ministry of Education and Research under the scheme “KMU-innovativ: Produktionsforschung” on an integrated sensor system for monitoring the braiding process (“Integriertes Sensorsystem zur Überwachung des Flechtprozesses – InSensoFlecht”, funding code: 02P16K553).

Contact Persons

Dr.-Ing. Swen Zaremba