Hexental – Hardware and software development for extrusion-based 3D printing for dental applications

Development of a 3D printer for the production of dental implants using an extrusion-based process.

Project Partners

GBN Systems GmbH

Duration

01.04.2021 – 30.09.2023

Funding authority

Federal Ministry for Economic Affairs and Climate Action

Motivation

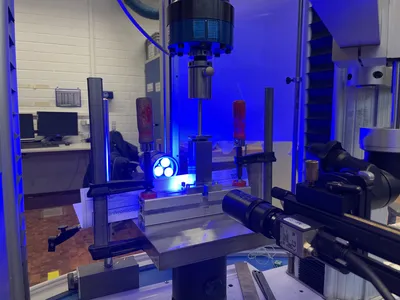

The Chair of Carbon Composites currently researches the 3D printing of reinforced materials with different fillers. The extrusion process is simple, offers cost and time advantages, and the geometrical accuracy of the dental implants is potentially comparable to the products manufactured with stereolithography technology. For this reason, this project aims to develop an extrusion process, both for high-viscosity and UV-curable materials. As a result, a more economical technique with high-quality standards will be offered compared to the stereolithography process.

Method

The aim is to use pastes already commercialized on the market as a highly viscous reaction material to produce dental implants in the extrusion process using UV. In addition to the project management, different subtasks are to be worked out: (1) the material characterization under the process boundary conditions, (2) the print head development, (3) the development of the light-curing unit, (4) the development of a cartridge system for material handling, (5) a color change system, (6) a polishing unit, and exclusively (7) the testing of the component.

Acknowledgement

The chair acknowledges the project's funding, "Development of hardware and software for extrusion-based 3D printing of dental applications - Hexental", granted by the Federal Ministry for Economic Affairs and Climate Action under the Central Innovation Programme (Funding number: KK5135802LU0).

Contact Persons

Margarita Etchegaray Bello, M.Sc.; Dr.-Ing. Swen Zaremba