FasSAd – Fiber-reinforced Saltcores for Aluminum Die Casting

To achieve maximum lightweight potential and functionalization in aluminum parts, we are developing a novel kind of lost core material: A fiber-reinforced salt core, which is able to bear higher loads with less crack sensitivity that widens the design freedom beyond the state of art for known lost core technologies in casting and injection processes.

Project Partners

Haas Metallguss GmbH; Apppex Product Development, Prototypes, Parts GmbH

Duration

01.09.2019 – 31.08.2021

Funding authority

German Federal Ministry for Economic Affairs and Energy

Motivation

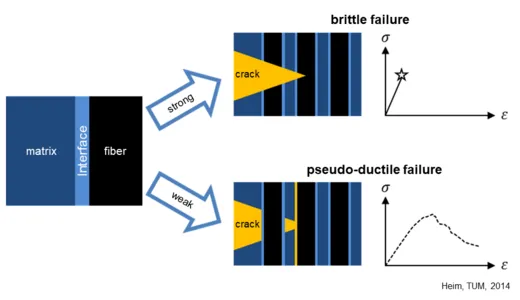

Salt cores are a well-known lost core material in automotive production lines, especially for motor components, such as piston cooling channels. The lost core enables hollow structures with undercuts in high-pressure die casting (HPDC) parts. They can be dissolved in water, but are sensitive to tensile stress like a ceramic. Thin cores with long unsupported lengths are impossible yet. Furthermore, their brittle behavior requires a compromise when choosing the parameters like the injection speed that affects directly the cycle time. In order to increase the robustness of the whole process and to push the lost core limitations beyond the state of art, the composite technology is investigated within the project. The expected benefits are higher production rates of HPDC parts and more complex hollow geometries that are required for the powertrain in electric vehicles, for example.

Method

The newly developed lost core system bases on composite technology. It combines the benefits of the salt (water-soluble, temperature stability) with the benefits of the reinforcement fiber material (tensile strength). The main effect is the “pseudo-plastification” of the brittle salt matrix by adding short, long or endless fibers. The fiber bears the tensile load and reduces crack and bending sensitivity dramatically. Thermal shock resistance is also expected to be increased due to thermal conductive fiber material. Several tooling and process concepts will be investigated in order to produce fiber-reinforced salt cores. The specimen will be tested thermo-mechanically in lab and under real production conditions on a HPDC machine. Also recycling capabilities will be investigated. The rather high cost of the fiber can be attenuated by reusing them over many cycles. The easy separation from the water-soluble matrix material is a big advantage from the ecological as well as the economical point of view.

Publications

Boos, D.: Fiber-Reinforced Salt Cores for High-Pressure Casting Processes, 26. Nationales SAMPE Symposium, TUM, 09.02.2021

Acknowledgement

The chair thankfully acknowledges the funding provided by the German Federal Ministry for Economic Affairs and Energy under the scheme “Zentrales Innovationsprogramm Mittelstand (ZIM)” on the research project dealing with fiber-reinforced salt cores for aluminum die casting (“Faserverstärkte Salzkerne für den Aluminiumdruckguss – FasSAd”, funding code: ZF4004317LL9).