ExtRa-hiPer – Large Scale Extrusion and Robot Based 3D Printing with Software Solution for High Throughput Rates with High Performance Materials and Continuous Reinforcement

The aim of the project is to enable the additive production of components made of high performance polymers with continuous fiber reinforcement on a large scale with high throughput rates.

Project Partners

SWMS Systemtechnik Ingenieurgesellschaft mbH, Dyze Design Inc.

Duration

01.10.2019 – 30.09.2021

Funding authority

Federal Ministry for Economic Affairs and Energy

Motivation

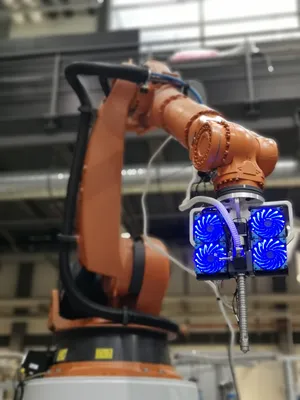

The usual procedure for the production of parts made of fiber reinforced polymers (FRP) using 3D printing processes is the integration of short fibers into the raw material which is going to be processed (filament or granulate). As a result, the mechanical properties of these parts are usually far behind those of conventionally manufactured FRP parts. The developments in ExtRa-hiPer will make the production of high performance FRP parts with 3D printing possible. The construction of a robot-based 3D printing system also allows the production of parts with dimensions of up to 2x4 meters. The aerospace industry is a potential field of application for this.

Method

In the project ExtRa-hiPer a combination of material extrusion and composite processing is being developed. This new process will enable the production of large structures with continuous fiber reinforcement. Initially, a new extruder for processing high-performance polymers in the form of granulate is being developed. In a second step, the integration of continuous fibers into the production process will be implemented. A cutting system will be developed for this purpose. In order to ensure a load path compliant deposition of the fiber reinforced material, a software solution with offline path planning will be developed.