EntEnBau – Development of a continous fiber coextrusion process with thermoplastic and thermoset matrix with actively controlled conditioning of the build space

The aim of the project is the development of a continous fiber coextrusion process with a thermoset-thermoplastic material combination, a material feed in the process with a sensory build space monitoring and conditioning.

Project Partners

myprintoo GmbH

Duration

01.04.2020 – 31.03.2022

Funding authority

Federal Ministry for Economic Affairs and Energy

Motivation

Extrusion-based 3D printing is one of the most widespread technologies for the production of additive-based components. Nevertheless, apart from demonstrators and design studies, only a few relevant components are manufactured using this process. This can be attributed to quality-related limitations of the process. Often required mechanical component characteristics are not achieved due to the layered structure of the components. Furthermore, chemical reactions and other influences that have been largely neglected up to now result in poorer layer adhesion. The use of thermosets and continuous fibers could achieve higher strengths. Compared to thermoplastics, thermosets have a higher stiffness and hardness and hardly tend to deform under load and heat.

Method

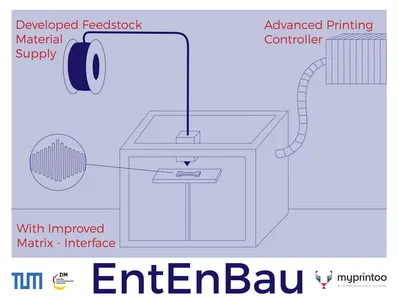

The aim of the project is to develop a coextrusion process in a controlled atmosphere of thermoplastic matrix material together with continuous fibre strands impregnated in a thermoset to create a better bond between the individual strands and layers and thus achieve high component strengths. The main challenges here include the generation of a bond between the continuous fiber material and the surrounding material. Furthermore, a new material feed for the filament has to be developed. In order to increase the print quality and layer adhesion of the individual layers, build space conditioning and air guidance will be developed. Furthermore, an emission-related monitoring and control of the extrusion process is installed.

Acknowledgement

The chair thankfully acknowledges the funding provided by the Federal Ministry of Economic Affairs and Energy as well as the AiF Projekt GmbH for the ZIM R&D Project “EntEnBau – Development of a continuous fiber coextrusion process with thermoplastic and thermoset matrix with actively controlled construction space conditioning” (funding code: DF4004325KO9)