ADAPT-H2-Tanks – Adaptive Design for Advanced Performance of Type 4 H2 Tanks

The project aims to develop type IV hydrogen pressure vessels for cuboidal installation spaces in vehicles, whereby the main challenges lie in the production of the plastic liner, the CFRP structure and the calculation of suitable winding paths for the CNC winding machine.

Project Partners

Floteks Plastik Sanayi ve Ticaret A.Ş., Mefex GmbH

Duration

01.12.2024 – 31.01.2026

Funding authority

Federal Ministry for Economic Affairs and Climate Action of Germany (BMWK)

Motivation

Green hydrogen is a promising solution for the challenges of the energy transition, especially in mobile applications. While battery electric vehicles (BEVs) dominate as an alternative to internal combustion engine vehicles (ICEVs) in passenger cars, fuel cell electric vehicles (FCEVs) offer several advantages, especially for long driving ranges of more than 500 km. These include shorter refueling times and reduced seasonal driving range deviations. However, the production costs for FCEVs are higher compared to BEVs due to the lower production volumes. By using a common vehicle architecture for battery and fuel cell vehicles, costs could be reduced by exploiting economies of scale. However, this requires the hydrogen storage unit to be integrated into a flat cuboidal installation space in the vehicle underbody. With corresponding tanks instead of cylindrical ones, this installation space can be used more efficiently, so that a larger volume is available for H2, which enables longer driving ranges.

Method

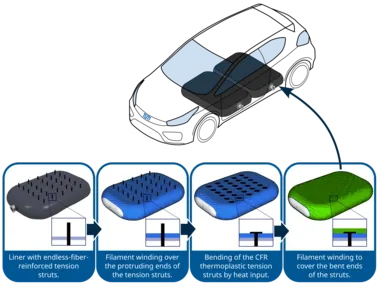

In the project ADAPT-H2-Tanks, the Technical University of Munich is working on the development of the CFRP structure and a suitable manufacturing process. In order to counteract the high bending forces in tanks adapted to the installation space, reinforcing structures in the form of continuous fiber-reinforced tension struts are integrated inside the tank. A particular focus is on the connection of these reinforcing struts to the tank wall. In the case of flat tanks, compacting the laminate also presents a particular challenge. The manufacturing parameters for the tension-strut-reinforced tank are being analyzed during the course of the project with the aim of improving the mechanical properties of the CFRP structure and ensuring reliable manufacturing of the technology demonstrator.

Acknowledgement

The Chair gratefully acknowledges the funding of the project “ADAPT-H2-Tanks” (funding code: KK5135821KL3) by the Central Innovation Program for SMEs (ZIM) of the Federal Ministry of Economic Affairs and Climate Action within the IraSME network.

Contact Persons

Elisabeth Gleis, M.Sc.; Dr.-Ing. Swen Zaremba