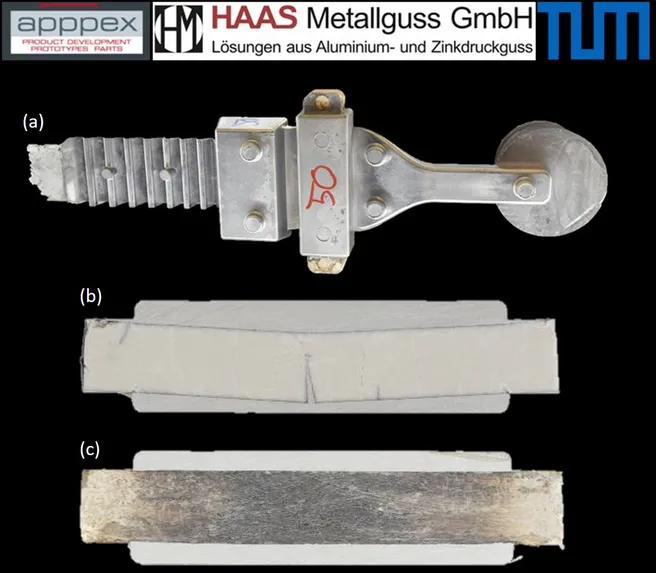

The FASSAD project (ZIM FKZ: ZF4004317LL9) consortium consisting of the companies apppex, Haas Metallguss and the Chair of Carbon Composites of the TUM successfully applied fiber-reinforced salt cores in aluminum high-pressure die casting (HPDC). HPDC is well suited for the economic production of complex shaped light-metal parts. However, the design freedom is severely restricted by the challenging process parameters. Within the project, a robust lost core material was developed. It is based on salt and enables undercuts in cast parts. After the casting it can be washed out with water and be recycled. The partners investigated various material combinations for this purpose, including ecologically and economically attractive natural fiber-reinforced salt cores. They were exposed to series process conditions. At the center of the tubular specimen, mold pressures of around 800bar were measured. The direct comparison with commercially available salt cores shows, that fiber-reinforced salt cores endure a real HPDC parameter set whereas ordinary salt cores fail. Now, the new, process-stable core material enables a HPDC foundry to produce hollow parts for a stronger functionalization or emission reduction.