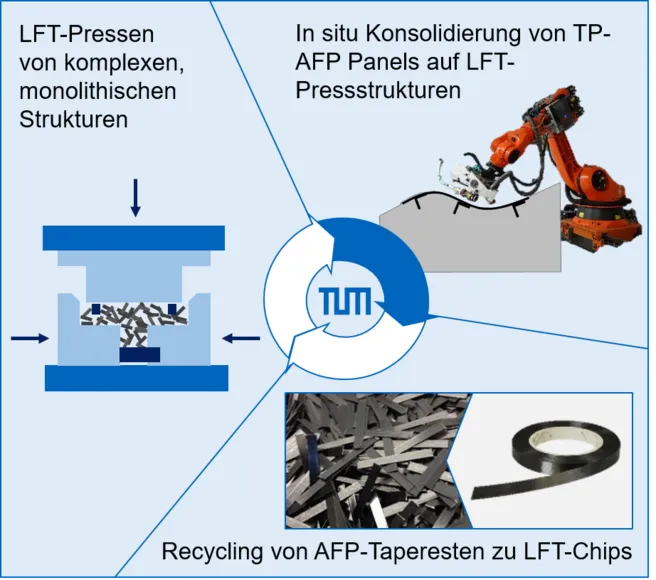

At the Chair of Carbon Composites the project REUSELAGE for the process development of pressed long-fibre reinforced thermoplastics (LFT) made of recycled CF/PEEK tape residues starts. During the production of CFRP structures by Thermoplastic Automated Fiber Placement (TP-AFP) on an industrial scale, waste residues of up to 20% are produced. Within the scope of REUSELAGE, a process for the preparation of these tape offcuts and subsequent pressing into complex monolithic components such as fittings or hinges is being developed. In a following process step, continuous fibre reinforced structures are to be consolidated in-situ to the LFT press structures by using TP-AFP. In the course of the process development, tools for the production of a hybrid CF/PEEK demonstrator consisting of a pressed LFT component and an in-situ consolidated TP-AFP structure will be developed. The combination of LFT pressing and TP-AFP process promises particular application potential through integral design, reduction of joining processes, recycling of production waste and recyclability through "one material".

The REUSELAGE project is funded by the Central Innovation Programme for small and medium-sized enterprises (ZIM) from the Federal Ministry of Economic Affairs and Energy (BMWi).