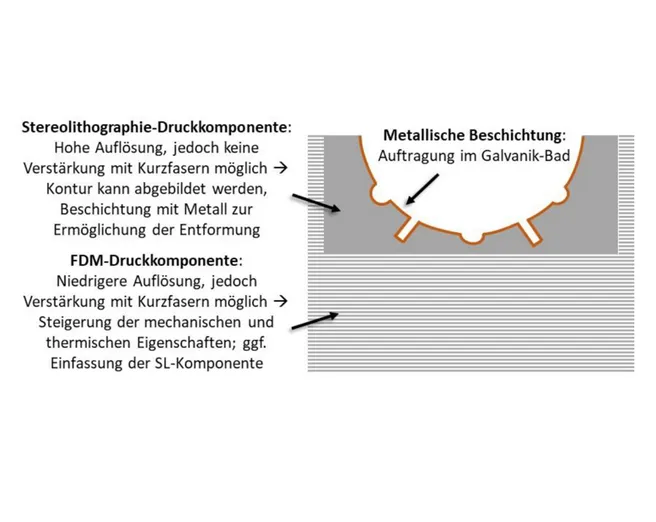

The project "3DMeKa" has started at the Chair of Carbon Composites (LCC). The project consortium consists of Jürgen Kleine GmbH, WIOTEC Ense GmbH & Co KG and the Chair of Carbon Composites at TUM. The aim of the project is to develop a process for manufacturing novel injection molds based on additively manufactured fiber-reinforced plastics with a micrometer-thick metal coating. The innovative solution approach for the mold tool consists of the combination of two additive processes in interaction with a metallic coating. The respective advantages are combined to drastically reduce production time and costs. With the aid of the metallic coating, the thermal conductivity and service life of the injection mold is to be significantly increased. With the aid of this new mold technology, the existing approach (aluminum cavity) will be supplemented by a further alternative to enable future injection molded components to be tested quickly and cost-effectively.

The new project is funded by the Central Innovation Program for SMEs (ZIM) of the German Federal Ministry of Economics and Climate Protection.

News

New project „3DMeKa“ has started