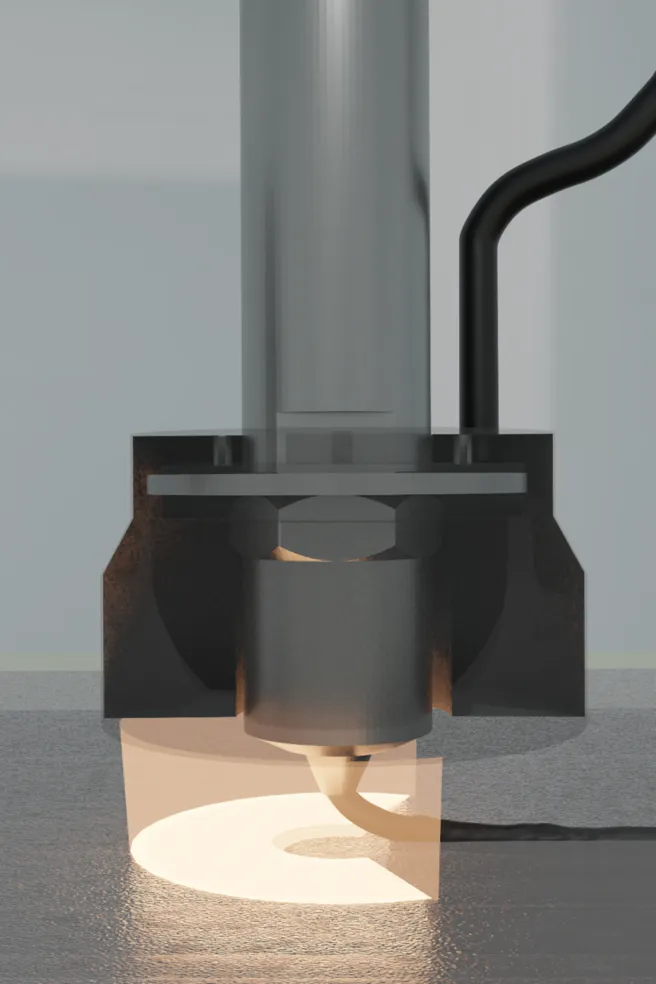

The Chair of Carbon Composites has started a new project “MEX-DES: Additive Manufacturing by Material extrusion with Directed Energy Substrate Preconditioning”. With the project objective of printing the 3D structures with carbon fiber reinforcement on a large scale, a new additive manufacturing process based on material extrusion and directed energy processes will be developed. By using an active laser for the pre-heating of the substrate, the interlayer bond strength can be increased and high geometric accuracy can be guaranteed. In cooperation with the professional laser manufacturer Dr. Mergenthaler GmbH, the laser system to be developed will be suitable for the in-line preconditioning of various material substrates. The developed laser system and a material extruder (offered by associate partner Dyze Design) will be integrated as one manufacturing unit, which can be flexibly installed on any kinematic system such as an industrial robot arm. A cooperative control system under the consideration of different printing conditions will be developed for the new process to realize high-quality automated manufacturing on a large-scale. This project is funded by the German Federal Ministry for Economic Affairs and Energy within the Central Innovation Program for small and medium-sized enterprises.