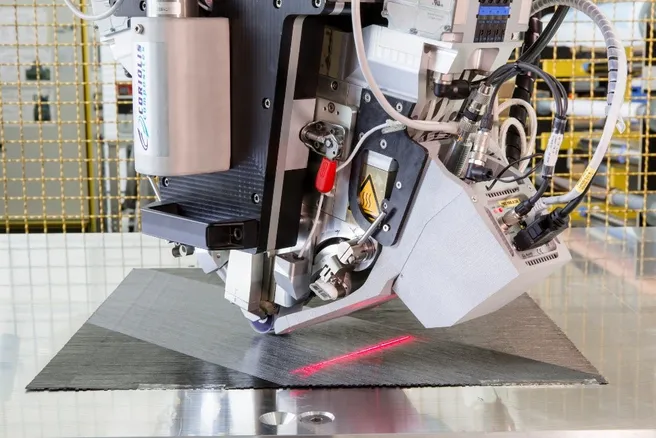

At the LCC, new approaches have been investigated that allow visual inspection in the Automated Fiber Placement process to be reduced to a minimum. The resulting decrease in machine downtime leads to a direct increase in productivity in an industrial manufacturing environment. Within the framework of the joint research project Integrated System for Process Chain Data Acquisition (ISP), the LCC, together with its partners InFactory Solutions, fortiss, Cevotec, Ariane Group and DXC Technology, has developed new ways of making machine parameters and process variables in AFP accessible for automated evaluation. In this context, the prototype of an optical quality inspection system was integrated into an industrial AFP machine. By means of comprehensive lay-up trials, the relationships between process variables, occurring defects and their effects on the component were investigated and the automated inspection of the manufactured parts was demonstrated.