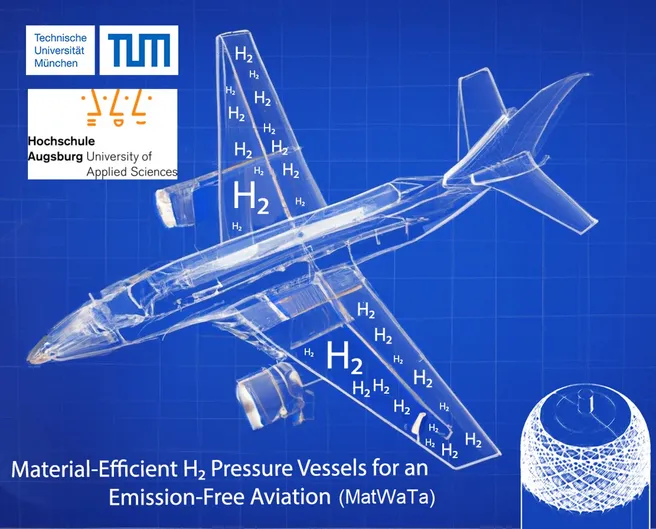

A new research project has started at the Chair of Carbon Composites (LCC) of TUM. The project "MatWaTa" aims at material-efficient production of hydrogen pressure vessels for an environmentally friendly and emission-free aviation. Using an innovative combination of three process technologies (filament winding, tufting and fiber-patch-placement), the material-efficient production of pressure vessels is investigated. Reinforcing the dome area of a pressure vessel by the means of fiber-patch-placement and tufting, a 20% reduction in material usage and production time is anticipated. LCC is dedicated to the task of concept development and realization of the multi-process manufacturing, as well as fabrication and testing of the tank demonstrators. Augsburg University of Applied Sciences cooperates in the research area of simulation and optimization of the demonstrator structures. The project is expected to run through Dec. 31, 2025.

The project is funded by the Aviation Research Program of the Bavarian Ministry of Economic Affairs, Regional Development and Energy (StMWi) as part of the Holistic Air Mobility Initiative.

Contact:

Shima Norouzi, M.Sc.; e-mail: shima.norouzi(at)tum.de

News

Development of Material-Efficient Hydrogen Pressure Vessels in Project "MatWaTa"